Precision planter

Onion planting, the new standard

Planting onions with the precision of sowing. WIFO has developed the unique Precision Planter (PP) system especially for this purpose. The Precision Planter is the solution for planting high-quality bulb crops from 8 to 35 mm (optional up to 50 mm). Besides onions, the Precision Planter is also suitable for shallots, garlic and minitubers.

Efficient planting with maximum result

A higher yield starts with a regular planting distance. With the Precision Planter System, WIFO is taking planting of onions to a higher level, ensuring a consistent planting distance. This gives the onions sufficient space to develop, resulting in a uniform appearance, uniform bulbs and an optimal and highquality yield. The Precision Planter System keeps the number of doubles to a minimum, so there can be made optimal use of the planting material.

|

"We see that the WIFO planter distinguishes itself by precision in combination with high capacity. With this, we are able to expand the annual planted area up to more than 100 hectares. The precise distribution ensures a good spreading of the planting material, which results in a higher yield and higher quality. The optimal distribution over the available area also saves on planting material.

Martijn Laan, Loonbedrijf Sturm-Jacobs |

Read more about the precisionplanter

Precision at high capacity

With the WIFO Precision Planter, you can plant at an accurate planting distance with a driving speed up to 6 km per hour. This allows the Precision Planter to achieve almost a double capacity compared to a pneumatic onion planting system (max. 3,5 km per hour). The Precision Planter has an easy to fill bunker. From the bunker, the planting material is led to the elements via adjustable dosing valves. The onions are laid in a single row by means of the onions vibrating system, after which they are carefully laid through the pintle belt.

Control of precision

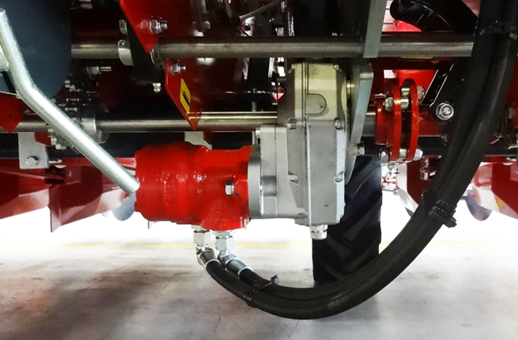

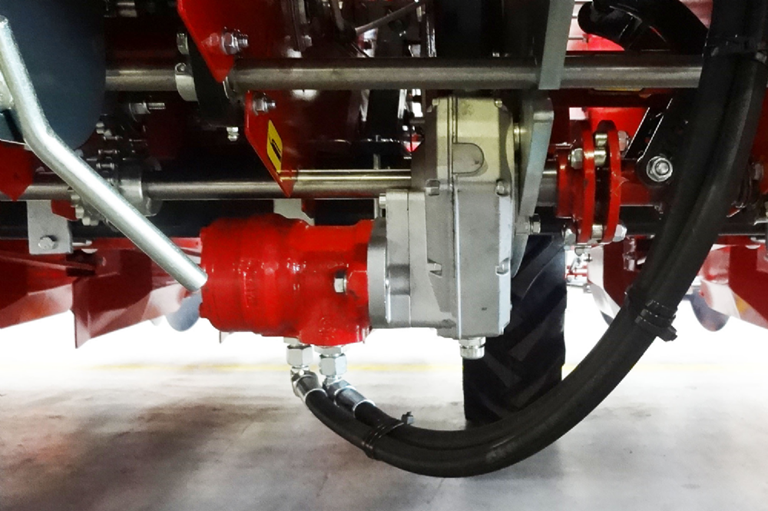

In order to keep an eye into the progress of planting, it is possible to provide the Precision Planter with an output check. By providing one or more rows with sensors, the desired output can be checked via the Müller Precimat. With the hydraulically driven precision planter, the belt speed can be adjusted automatically via the Müller Uni-Control S terminal. This means that the number of plants per meter always remains the same with a varying bulb size.

The Koningsplanter

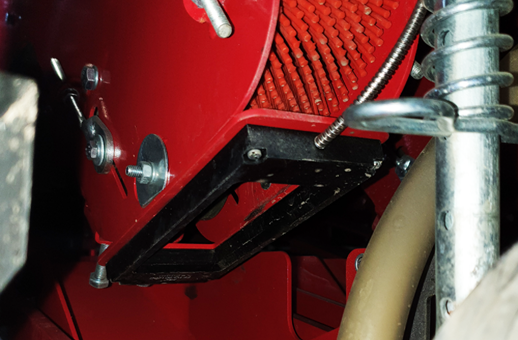

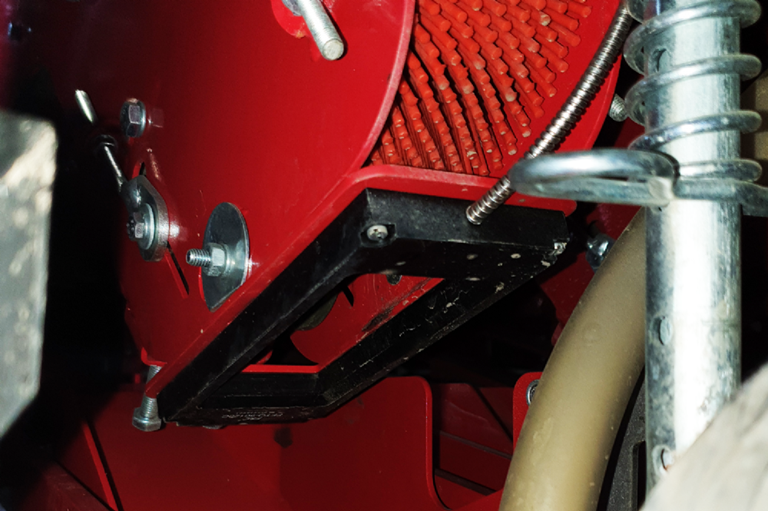

The WIFO Precision Planter has the renowned plantation element of the Koningsplanter. Over the years, the Koningsplanter has proven to take onion planting to a higher level. The PP is user-friendly and easy to adjust to the desired planting distance. The parallel suspension of the planting share not only keeps the distance but also the depth constant.

Precision planting

■ Minimum quantity of doubles

■ Optimal growth space

■ Saving on planting material

■ Higher yield

■ More uniform harvest result

Benefits:

■ More capacity due to high planting speed

■ Variation in the size of the planting material is not a restriction

■ Easy to operate and adjust

■ User-friendly

| Type |

Width

|

Height

|

Length

|

Track width

|

Row widths

|

Hopper capacity approx.

|

Weight

|

Number of rows

|

|---|---|---|---|---|---|---|---|---|

| PP40-300 | 2000 mm | 1750 mm | 2350 mm | 1500 mm | 30 cm | 1,5 m3 (± 750 kg) | 850 kg | 4 |

| PP50-250 | 2050 mm | 1750 mm | 2350 mm | 1500 mm | 25 cm | 1,3 m3 (± 650 kg) | 900 kg | 5 |

| PP50-300 | 2350 mm | 1750 mm | 2350 mm | 1800 mm | 30 cm | 1,4 m3 (± 700 kg) | 975 kg | 5 |

| PP50-350 | 2700 mm | 1750 mm | 2350 mm | 2250 mm | 35 cm | 1,6 m3 (± 800 kg) | 1050 kg | 5 |

| PP60-250 | 2350 mm | 1750 mm | 2350 mm | 1800 mm | 25 cm | 1,5 m3 (± 750 kg) | 1200 kg | 6 |

| PP60-270 | 2500 mm | 1750 mm | 2350 mm | 2000 mm | 27 cm | 1,6 m3 (± 800 kg) | 1250 kg | 6 |

| PP60-300 | 2550 mm | 1750 mm | 2350 mm | 2000 mm | 30 cm | 1,7 m3 (± 850 kg) | 1250 kg | 6 |

| PP60-500 | 3500 mm | 1750 mm | 2350 mm | 3000 mm | 50 cm | 2,4 m3 (± 1200 kg) | 1400 kg | 6 |

| PP70-250 | 2800 mm | 1750 mm | 2350 mm | 2000 mm | 25 cm | 1,7 m3 (± 850 kg) | 1300 kg | 7 |

| PP80-250 | 2700 mm | 1750 mm | 2350 mm | 2250 mm | 25 cm | 1,9 m3 (± 950 kg) | 1400 kg | 8 |

| PP80-500 | 4550 mm | 1750 mm | 2350 mm | 4050 mm | 50 cm | 3,2 m3 (± 1600 kg) | 1900 kg | 8 |

| PP80-300/600 hydr. | 3700 mm | 1750 mm | 2350 mm | 1500 mm | 30/60 cm | 2,6 m3 (± 1300 kg) | 1600 kg | 8 |

| PP100-250 | 3600 mm | 1750 mm | 2350 mm | 3000 mm | 25 cm | 2,5 m3 (± 1250 kg) | 2500 kg | 10 |

| PP110-250 | 3600 mm | 1750 mm | 2350 mm | 3000 mm | 25 cm | 2,5 m3 (± 1250 kg) | 2500 kg | 11 |

Options |

Additional price |

|---|---|

| Trackwidth and/or row distance different than standard | On request |

| Moving bunker valve to prevent blockages | On request |

| Discs instead of plates to cover (per row) | On request |

| Additional press wheels behind the cover discs (per row) | On request |

| Adjustable height pintle belt for garlic, shallots and mini tubers (per row) | On request |

| Wide release belt for shallots (per row) | On request |

| Individual row stop manual by closing the planting element (per row) | On request |

| Precimat controller / counter + divider excl. sensors. Only for planter with mechhanical drive. | On request |

| Hydraulic drive incl. display and controller, excl. sensors With >10 rows compulsary choice. | On request |

| Sensor set (per row) | On request |

| Ladder left and right of the plateau | On request |

| Hopper extension 30cm + 45% extra capacity (per row) | On request |

| Hopper extension 60cm + 90% extra capacity (per row) | On request |

| Lighting set rear (LED) + front + road signs | On request |

| Marker (manual) | On request |

| Marker by tractor hydraulics | On request |

| “Gandy” (granulate) spreader | On request |

| Chemical spray unit | On request |

| Pressure on cover discs | On request |